Drone Inspection

Close Visual Drone Inspection

Internal Drone Inspection

Thermal Drone Inspection

Use drone technology to improve safety, save time and money, and improve data quality during inspection of hard-to-reach assets.

Visual inspections of confined, internal, underground, high-up, over-water, and other generally difficult-to-access areas have traditionally been conducted using scaffolds, working platforms, and rope-access.

These methods result in personnel working in risky situations, longer task durations, higher task costs, and typically lower quality inspection images than a drone-based method for close and general visual inspection.

Our skilled remote pilots and advanced drone and sensor equipment ensure ease of access without additional working platforms, rapid deployment, task cost-savings, absolute quality of data, and most of all improved safety for personnel during general and close visual inspection of assets.

Case Study

Internal Drone Inspection

Improving Mine Safety with the Elios 3 RPAS

Close Visual Drone Inspection

Azure are experts in drone inspection services utilising our market-leading drone, photography, and survey technologies.

The use of drones allows for safe, efficient, and thorough assessments of hard-to-reach and hazardous areas, minimising the need for costly and time-consuming manual inspections.

Our team have successfully carried out drone inspections on mine infrastructure, refineries, power stations, bridges, jetties, bulk export loaders, and power networks.

Internal Drone Inspection

Azure specialises in complex internal inspections using our in-house Elios 3 RPAS and experienced pilot team.

Increase safety, reduce downtime and inspection costs, and improve asset information quality all while removing the need for workers to enter dangerous confined environments with our collision resistant confined space robotics and skilled remote pilots.

Our team have successfully carried out missions with the Elios 3 in confined spaces such as storage tanks, culverts, bridges, grain silos, boilers, chimneys, piperacks, and underground mines.

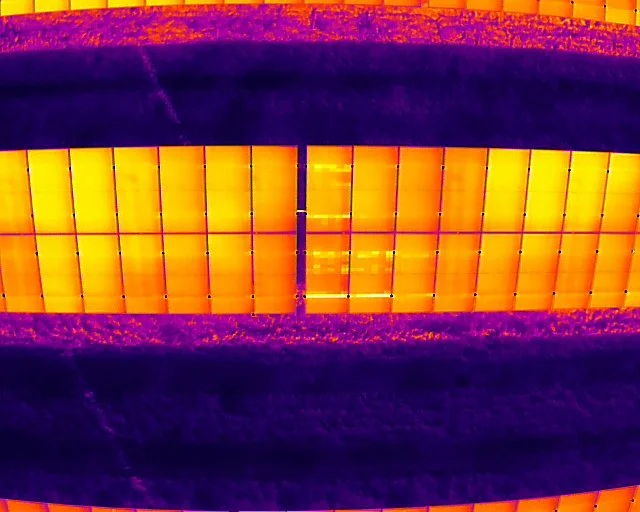

Thermal Drone Inspection

Azure is experienced in large-scale aerial and handheld thermographic inspections.

Thermographic inspection using drone-mounted radiometric cameras provides rapid coverage of large areas and high-resolution radiometric images for heat-based condition monitoring of solar farms and supporting power infrastructure assets.

We have delivered thermal condition assessments of solar PV modules, isolator box and inverter DC terminations, general electrical connections, power transmission connections, and substation componentry.

Project Examples